TactiLearning Featured in Crane Network's Crane & Lifting News

TactiLearning and the trend towards Hands-On Training were featured in Crane Network's Crane & Lifting News in July. Roger "Skip" Ohman discussed the advantages of hands-on training and provided an interactive rigging quiz for the reader. Read the full article here.

TactiLearning Hosts Hands-On Training at ACRP General Assembly

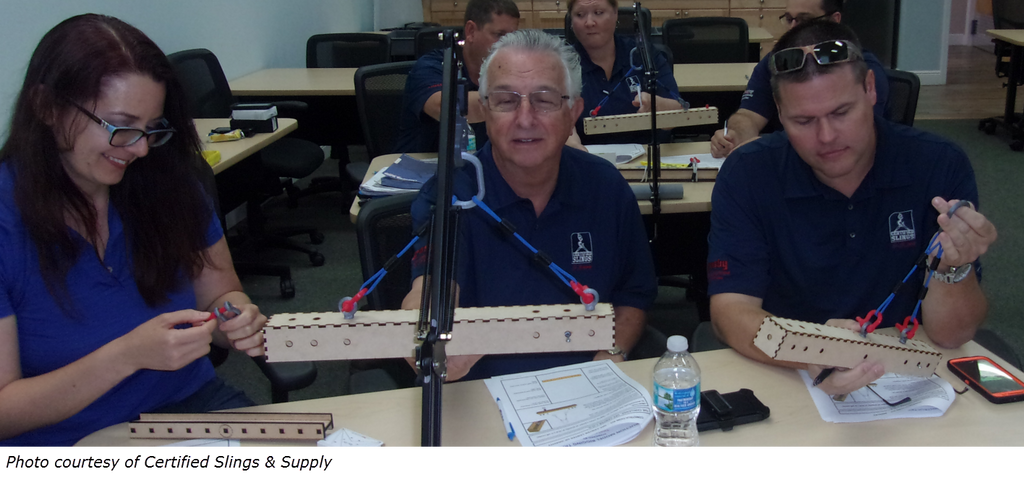

TactiLearning ran an all-Assembly workshop on techniques for 'hands-on' training at the ACRP General Assembly May 10th in Tulalip, Washington. Participants were grouped into teams and equipped with TactiLearning Model Rigging Training Kits to face 10 rigging challenges designed by renowned industry expert Roger "Skip" Ohman to demonstrate a hands-on approach to rigging training.

TactiLearning Presents Hands-On Training Techniques at AWRF Spring General Meeting

TactiLearning's Roger "Skip" Ohman gave a presentation on techniques for hands-on training at the AWRF Spring General Meeting April 23rd through 25th in Savannah, Georgia. Participants were equipped with the latest TactiLearning Model Rigging Training Kits designed for the unique needs of the construction industry as Mr. Ohman demonstrated the advantages of hands-on training.

The START to Good Rigging

Accidents can result from rigging problems or equipment failures. The more often we expose ourselves to risks, the more likely a problem or failure will occur. We improve safety in rigging by reducing risk. The rigger has three key responsibilities under OSHA and the ANSI/ASME standards. BE KNOWLEDGEABLE USE THE GEAR CORRECTLY REGULAR INSPECTION AND MAINTENANCE These form the foundation that good rigging practices are based on and they all require training. Recognizing questions to ask ,and knowing where to get the answers, is what risk management is all about. The rigging plan is an important tool in making sure...

"Awareness Training" Just Doesn't Cut It Any More

There's a powerful trend happening. Videos, PowerPoint presentations, and even interactive online classes and learning modules may seem like they are using the latest that technology has to offer. But these types of training experiences can only make you aware of information. "Performance-Enhancement Training" is the new frontier in training. Beyond the digital technology of what you can project on a screen is the learning technology that puts your hands to better use than just clicking a mouse. There's just no substitute for practice. Functional 3D models have been used successfully in different industries for decades, such as the hands-on...